Tetra Pak: review of a sustainability journey

A few weeks ago, I was invited to visit with Tetra Pak U.S. executives to hear about their sustainability commitments and to share my thoughts with you. I saw how Tetra Pak cartons are made, how they can be recycled and I had a chance to ask as many questions as I wanted on sustainability challenges they face and how they are addressing them as a company.

Tetra Pak is a multinational food packaging and processing company founded in 1943 by Ruben Rausing. In 1955, he came up with an innovative process to package liquids such as milk and cream in a way to better protect its contents and make distribution more efficient all while using minimal material. This all laddered up to a larger belief that a package should “save more than it costs”.

More than 60 years later, the concept is still quite the same but improvements have been made, especially when it comes to materials used and processing. To get a better idea of how Tetra Pak aseptic* cartons are made, I’ve outlined its manufacturing in the following steps:

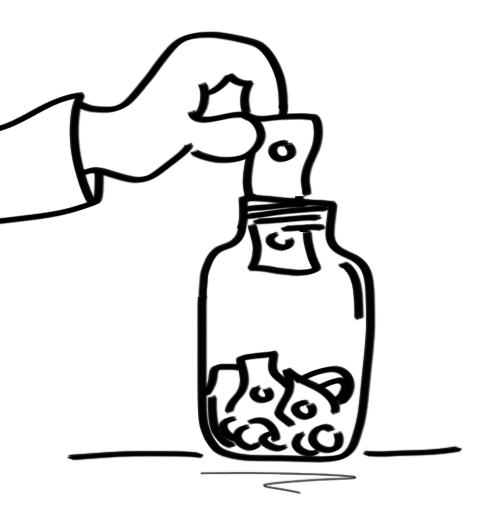

- Printing the package design onto a large roll of paperboard, 100% of which comes from certified forests and/or controlled sources;

- Adding a layer of polyethylene (plastic) on the outside to protect the carton;

- Adding a sealing layer of polyethylene and another very thin layer of aluminum foil on the inside, which protect the contents from oxygen and light until it is opened and makes it “shelf stable” for up to a year;

- Adding another thin layer of polyethylene on the inside to protect the contents;

- Slicing the large roll into smaller rolls;

- Sealing the paperboard into a tube;

- Filling the tube with product;

- In some cases, adding a cap on top.

Sustainability benefits of Tetra Pak cartons

In my opinion, the main sustainable quality of Tetra Pak’s aseptic cartons is that they protect food without preservatives, avoid food loss and help make products available in some parts of the world where refrigeration is not always an option. The cartons are also lightweight, especially compared to glass, so there are fewer carbon emissions from transportation.

Sustainability challenges Tetra Pak faces

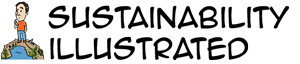

Certainly the biggest sustainability challenge for Tetra Pak is the recycling of cartons. Tetra Pak depends on consumers and local recycling facilities to recycle cartons. The below video gives a deeper dive into how carton recycling works. As many other multinational manufacturing operations companies do, Tetra Pak also depends on consumers to choose its cartons instead of reusable containers.

How Tetra Pak addresses those challenges

It was inspiring to meet Tetra Pak’s employees and to see their dedication to address these challenges and create sustainable products. They recognize where they can improve in their sustainability efforts and they are actively seeking and implementing solutions to be more sustainable across the value chain. Here are some examples of how Tetra Pak is addressing its sustainability challenges:

- They have created water-based inks to reduce air pollution;

- They are exploring graphene as a carbon-reducing material alternative;

- They are committed to responsible sourcing and work with certification bodies like FSC (Forst Stewardship Council), ASI (Aluminium Stewardship Initiative) and Bonsucro to ensure the raw materials in their packages are sourced responsibly;

- In 2014, Tetra Pak launched the Tetra Rex®, a carton that is made with bio-based polyethylene and uses a plant-based cap;

- The US headquarters I visited runs on 100% renewable energy, 6% of which is produced by their solar array on campus. Their goal is to run 100% on renewable energy worldwide by 2030;

- As a food-processing provider, Tetra Pak is in the position of the “middle man” who can help reduce the ecological footprint of an entire value chain. They are taking more and more of a leadership role to help their customers make more sustainable products and make the food & beverage industry more sustainable as a whole;

- Tetra Pak advocates for carton recycling:

- Used cartons can make valuable materials for new, everyday products. After being compacted into sheets in a hot press, cartons can be made into building material that can be used for roofing and wall systems. By separating the fibre (paperboard) from the aluminum/ polyethylene mix, the fibre then goes into the paper recycling stream to make paper products such as tissue paper, toilet paper, plant containers, cup holders, etc. while the aluminum/ polyethylene mix can be turned into new composite products such as benches, rulers, folders, mouse pads, etc.

Tetra Pak educates their customers (i.e. the food and beverage companies that choose to package their product into Tetra Pak cartons) to improve the recyclability of cartons. For instance, when Tetra Pak has encouraged their customers to include the

Tetra Pak educates their customers (i.e. the food and beverage companies that choose to package their product into Tetra Pak cartons) to improve the recyclability of cartons. For instance, when Tetra Pak has encouraged their customers to include the

“recyclable” logo on their cartons, it has doubled the recycling ratio of the cartons;- They also collaborates with competitors through the “Carton Council” in the US and in Canada to improve access to carton recycling;

- Tetra Pak also supports innovation and invests into new technologies such as robotic systems at Material Recovery Facilities to help better sort cartons.

For Tetra Pak to be 100% sustainable, they need their cartons to be recycled. Carton recycling access in the U.S. has increased by 350% over the past 10 years. However, there is still a lot of work to be done since only 61% of households in the US had access to recycling in 2019 and the carton recycling rate was only 16%. In conclusion, if we want to enjoy the convenience and food safety benefits of a Tetra Pak carton or any other container, we all need to make sure we do our part and put it in a recycling bin after using it.

To learn more about sustainability, please feel free to visit our library our short sustainability videos and cartoons.

* Aseptic processing, which allows products to be shelf-safe without preservatives, involves three primary steps: thermal sterilization of the product, sterilization of the packaging material, and conservation of sterility during packaging. Read more here.